Vacuum Bonding & Other

Methods of Attachment

The following installation methods are used for the

application of ceramic tiles:

ADHESIVE

BONDING

- Two-part epoxy or Silicone Adhesives

- Vacuum Bonding

MECHANICAL

ATTACHMENT

- Weldable tiles

- Interlocking

VACUUM

BONDING TECHNOLOGY

|

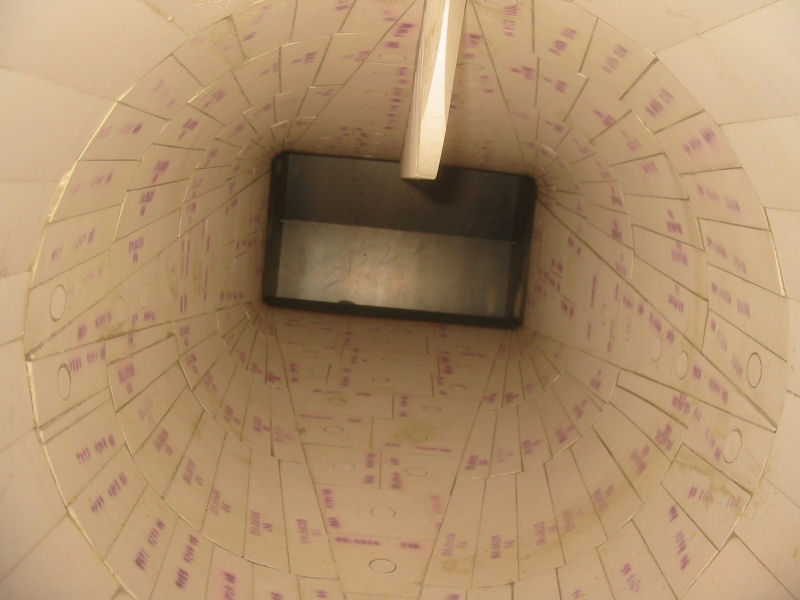

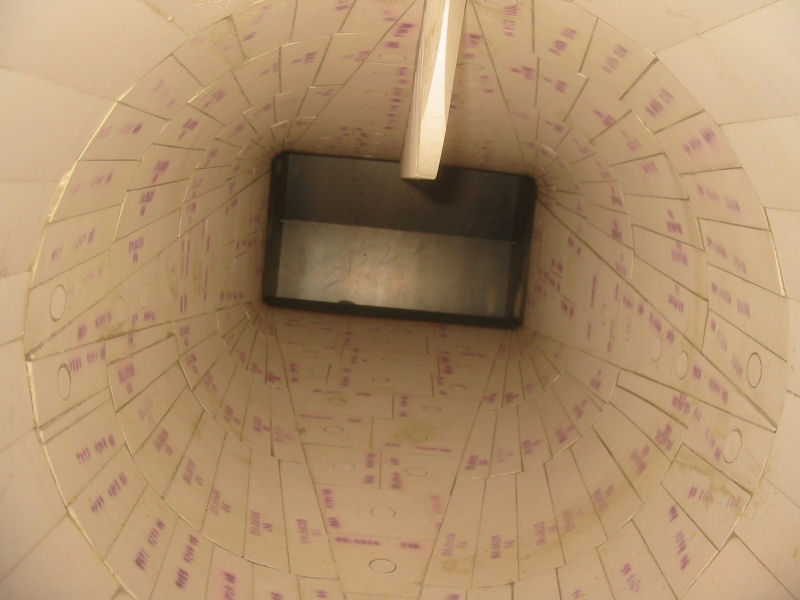

Vacuum bonding is an advanced bonding

technology that combines specialty structural

adhesives, wear resistant materials and

controlled processing.

Applications which require high reliability,

high impact resistance and wear protection are

ideal candidates for vacuum bonding

solutions.

Vacuum bonding has been refined by Thermo

Vac into a state of the art technology which

gives bonding strengths which can never be

achieved with standard adhesives.

|

|

Valuable features of vacuum bonded materials are:

- Increased impact resistance of hard wear resistant

ceramics. (See our video!)

- Unparalleled performance in dynamic applications

- Extremely high sheer strengths

- Proven performance in light weight designs with ceramic

linings as thin as 6 mm thick

- Existing equipment and complex shapes are lined without

redesign

- Bonded linings can be machined to fit tolerances

- Extremely high reliability in critical moving

applications

Vacuum bonding is an ideal solution in many tough

applications like:

- Fan blades

- Mixer housings and blades

- Valve gates

- Screw conveyors

- Pump volutes

A summary of the Thermo Vac´s vacuum bonding technology

gives the following qualities:

- The only bond for dynamic applications

- Used in most power plant applications

- Excellent for dynamic applications with high

stress

- Increased resistance to impact and vibration

- Maximum temperature for dynamic applications 135

°C

- Maximum temperature for static applications 325 °C

- High shear and tensile strengths; 31 MPa shear and 41.5

MPa tensile

- Highest installed cost for ceramics

BRAZING

|

Brazing is used to attach tungsten carbide

to steel substrates.

Very high bond strengths are achieved; 280 -

500 MPa tensile and 175 MPa shear.

It has full bond strength at 1000 °C, and

excellent impact resistance.

|

COMPOSITE

TECHNOLOGY:

MECHANICAL

ATTACHMENT

|

Weldable clips or interlocking shapes can be

used with most wear materials.

The combination of standard adhesives and

mechanical attachment provides a cost effective

system for medium or low impact

applications.

|

|

Summary of qualities:

- Mid-range installed cost for ceramics

- To be best used for static applications with medium

impact

- Secure attachment in higher temperatures

- To be used for applications with maximum temperatures

of 400°C

STANDARD

ADHESIVES

|

RTV Silicone and Two Part Epoxies are used

in low stress applications, usually together

with mechanically attached materials. Normal

maximum strengths are 7 MPa tensile and 5.5 MPa

shear.

RTV silicone is used in temperatures up to

260 °C and epoxy is used in temperatures up to

65 °C.

|

Summary of qualities:

- Lowest installed cost for ceramics

- To be used for static applications with low stress

- To be used for applications with minimal vibration or

impact

- To be used for applications with maximum temperatures

of 260 °C

- Low shear and tensile strengths; 5.5 MPa shear, 10 MPa

tensile

COMPOSITE TECHNOLOGY

|

The composite technology uses a variety of

dissimilar materials that when bonded together

form a system which is superior to the

individual components.

This sytem puts the strongest wear materials in

the highest wear area and the more cost

effective materials in the less intensive

sreas, all on the same wear

surface.

|

|