| CWMaterialTeknik | |||

|

||

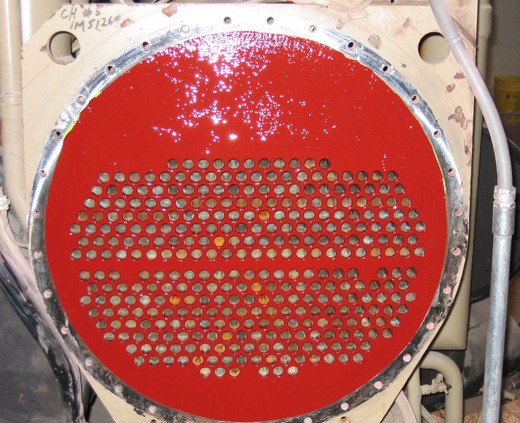

Protective Coatings

The Duromar line of products solves a number of industrial problems related to erosion, corrosion and process control. The key is the use of 100% solids, zero VOC, polymeric materials which are safe to use for the applicator and non-toxic to the environment. Duromar pioneers the field of applied polymeric technology. We offer a wide range of Duromar High Performance linings for the most severe corrosive and abrasive environments; and structural adhesives. On the program are also Repair and Maintenance materials for rebuilding, resurfacing and speciality maintenance products; concrete repair and flooring systems. The Duromar production facilities and quality control procedures are certified to ISO 9001: 2000 standards. The Duromar products are approved for import to all Countries in the European Union. All substances in the products are registered according to the REACH Regulations. CWMT works with the best and most experienced application experts to be found in Sweden; Corronix AB offers shot blasting, pickling, painting and coating in its own large shop as well as in the field. All assignments are carried out according to ISO 9002 standards. Summary of Advantages:

|

||

|

|

© Copyright CWMT.SE 2009. All Rights

Reserved.